MPP - MICROPRESS

- PRESTIGE

"Micro prestige"

Micro refers

to the company which produced fine mechanics and certainly not to the shape of

this huge press camera.

"Micro Prestige" is the headline of an article in the Amateur Photographer edition September 1956

and the article continued with

"few 5x4 cameras are held in higher regard by professional users than the

Micro-Press."

And yes, its huge impressing performance and beautiful design combined with lots

of essential features makes it a

dream for the real press photographer. I herewith present a nearer look at this

British competitor of the

US Graflex.

As said before the MPP Micropress is far from micro as its name might suggest.

In the contrary, it is a huge 4x5 format film camera with on top a huge build in

rangefinder. You'll see immediately some family traits pointing in the direction

of the US Graflex family and yes 80 percent of its design comes from the

Pacemaker Speed Graphic which needs no further introduction. There are however

some interesting details which never the less are very important. The drop bed

has another construction as well as the bed brackets. The rangefinder is of a

completely new design. Further more the lens standard slider and the track yoke

differs from the Speed Graphic which makes that both are not interchangeable

with the Graflex parts. The focal plane shutter seems to be the same, but closer

examination learns that there are huge differences.

The honourable

M.P.P. Micro-press

Made in Britain from 1950-1966 using American parts and Graflex

design.

By Jo Lommen

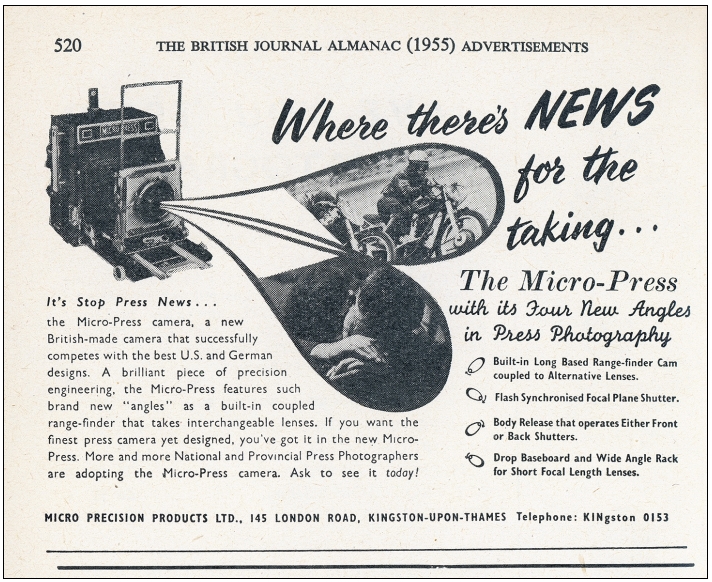

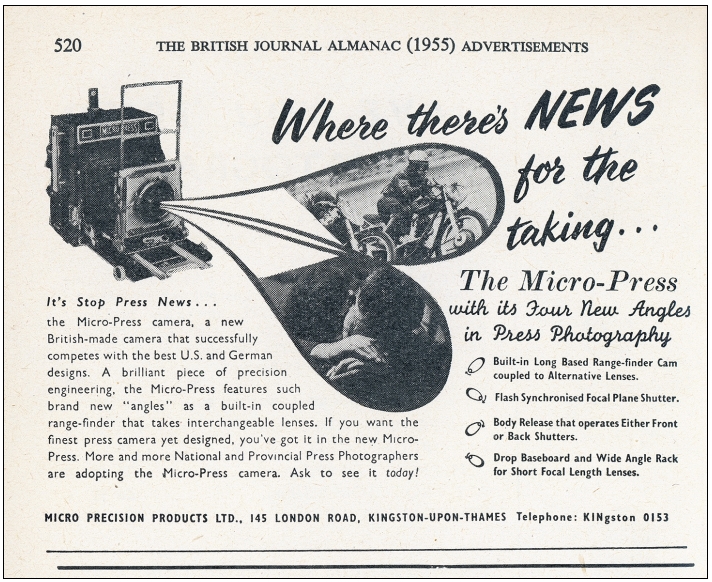

The Micro Precision

Products Ltd.

- 146 London Road Kingston

upon Thames Telephone Kingston 0153 -

The M.P.P 5x4 Micropress

Camera # 4084 year of production 1950

Real British press camera with American roots

.

Takes roll films, American

Grafmatic magazines and adaptor for 9x12 metal slides.

The M.P.P. Micro-press is designed and build to the ideals of leading

professional photographers. It gives a bit of performance of a studio camera

with the compactness, portability and simplicity of a press camera. It has the

utmost flexibility and will cope with difficult photographic problems whatever

their nature.

The Micro-press Camera has a

mahogany housing, leather bellows, drop baseboard to 30 degrees,

wide angle rack, dual extension, rising, tilting, cross and swing front, quick

release lens-panel, direct vision view finder, four way swing rotational

universal back with spring loaded slide holder and a slide lock to fix the

focusing rack. A single body release with slide selector for both focal plane

shutter and front shutters. Removable focusing

screen-hood. Cable release holder. Flash-gun bracket. Accessory shoe for sports

finder. Rangefinder instantly coupled to lenses by interchangeable cams. A

choice of accessories under which negative holders 2 1/4 x 3 1/4 or roll film

holders 4 1/2 x 3 1/4 inch. plates, sheet film and cut film is Grafmatic holder.

Weight 3250 gram. Dimensions 8x8x4 in.

Camera £ 85 Lens

extra.

In 1956 camera with 135 f/4,7 Xenar in Compur shutter with blade arrestor

cost £ 110,0.0

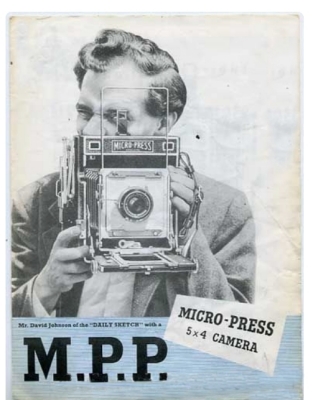

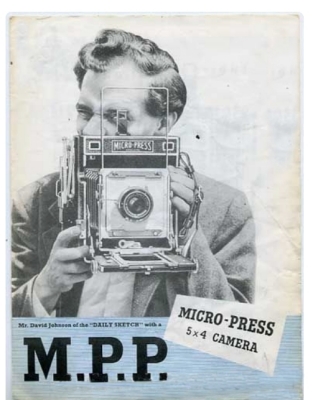

David Johnson of the Daily Sketch in a M.P.P. Advertisement.

The M.P.P. Precision retail price 85 Pound Sterling in the fifties.

At the first glance the M.P.P is a look alike of

the Pacemaker Speed Graphic. However there are some details that asks for a

nearer look. The first striking difference is the integrated rangefinder. Unlike

the Pacemaker Graflex top mounted rangefinder, the M.P.P. Micropress rangefinder

is an integral part of the camera body and gives the camera the unique and

striking design, undoubtedly the touch-of-the-fifties. The weight is at least as

touching as the design and the camera-man should have the strength of a boxer to

carry the huge camera with a weight of more than 5 kg which includes the flash

plus the 6 sheet Grafmatic holder. Carrying is one thing but holding the camera

in front of your face when focusing is another thing.

The open frame-finder should not be relied

upon to give the exact coverage of a subject, as the area seen through the

viewfinder will vary considerably from person to person and is greatly affected

if the operator is wearing spectacles. By the way, focussing can only be done

using the standard frame finder. Both windows on top of the camera

suggesting being an optical viewfinder or at least a part of it, are serving as

a rangefinder. The integrated rangefinder is coupled to the track with the lens

standard. Interchangeable cams make it possible to change lenses.

Having said that it is

about time to mention the positive side of this camera. Reason to take the M.P.P

Micro-Press in the hand and to open it and take a closer look. The

first thing we'll see are the brackets holding the drop bed. These are very nice

made and much better than the Graflex brackets. The eye catching top rangefinder

asks for attention. Comparing the to the top mounted Graflex viewfinder it is a relative easy

design and construction. The optical image and contrast as well as the working

of the mechanical coupling to the focusing rail are

perfect. At the first glance all other components look the

same as the Pacemaker Graflex camera. The lens-standard including its

frame-finder and lensboard-lock-sliders, the yoke between the drop bed guides,

the infinity stops, the build in release knob, the front shutter release

mechanic with its Bowden cable and last but not least, the bellows.

Non interchangeable parts!

In fact I'm sure originally these are

fundamentally the same components, but they won't fit, they are not

interchangeable with the Graflex camera! The lens standard does match the Graflex yoke, the yoke

doesn't fit to the Graflex drop bed guides and the shutter release mechanic

won't match the lens standard. The Graflex guide blocs would not fit to the

Micropress drop bed and the Graflex drop bed not to the Micropress camera.

Perhaps nice to know which Graflex part does match the Micropress. Well

that would be the build in release knob and the knurled wheels of the lens

standard. I'm pretty sure they used 80 percent of all the original Graflex parts

but made minor modifications. For what reason? It might have something to do

with the UK post war financial situation, or to prevent re-import from UK to

USA, or the bad economic situation in UK in those years. It would be nice

to find out the real reason about all this.

In the appendix

you'll find the interchangeable and non-interchangeable parts

with the Graflex camera.

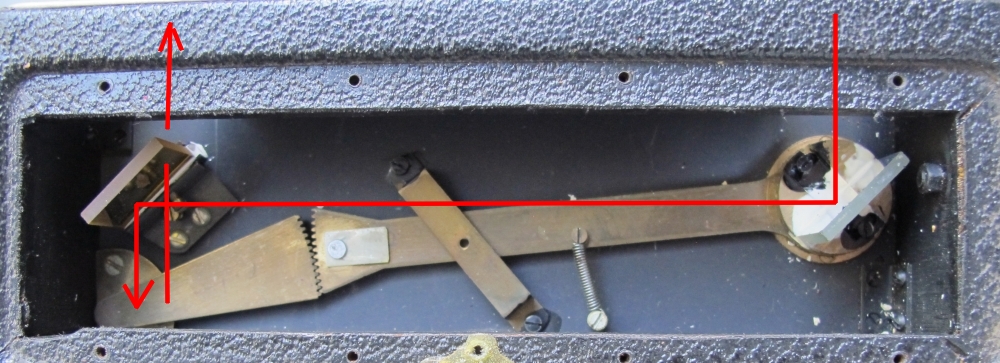

It's about time to get an idea of the inner of the Micropress

camera and we'll start right on the front with the rangefinder. Integrated in

the camera body, the prism and beam splitter located behind both windows are

connected by a fine mechanic steering mechanism to the plunger next the

exchangeable cam in the back rack. Turning the focusing knobs make the beam

splitter rotate around its axle and projects the image on the prism. The

photographer's eye

will see two images drifting together and coinside to one single image as soon

as the real distance to the subject has been focused. None of these optic components matches with any

Kalart or Graflex parts. Note the simple but efficient construction using a

tooth gear to couple the moveable cam with the right mirror. The left

mirror is a so called beam splitter. The left "port" receives the image of the

right mirror as well as the image strait forward and reflects half of the mirror

image while the other half stays transparent.

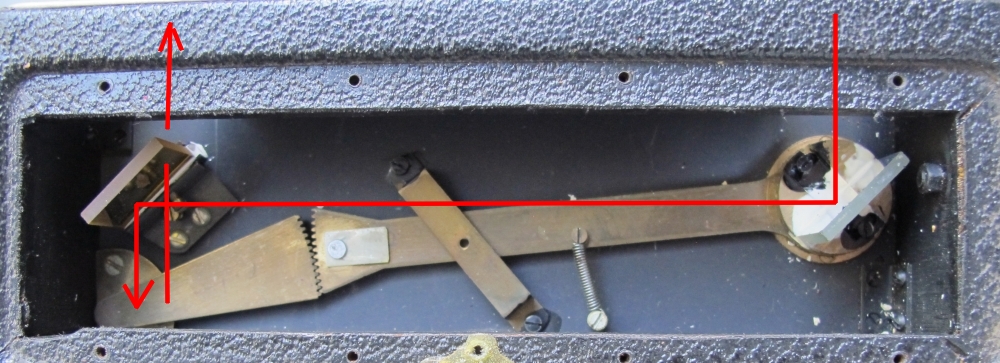

The movement of the Rangefinder is actuated by a cam which is

located on the focusing track back rack. The cam is fitted with dowel holes and is secured with

only one screw so that it is readily detachable. The cams are engraved with the

serial number of the lens with which they are associated. By these easily

interchangeable cams the rangefinder may be coupled to an infinite number of

lenses. This cam actuates a gear which is connected by a shaft that makes the

mirror rotating when focussing.

Minor differences between both cameras such as the infinity stops and the higher

positioned lens standard brackets (photos 3 and 4 ) make it impossible to

exchange parts from Graflex to M.P.P. or the other way around.

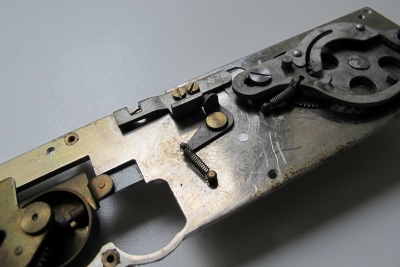

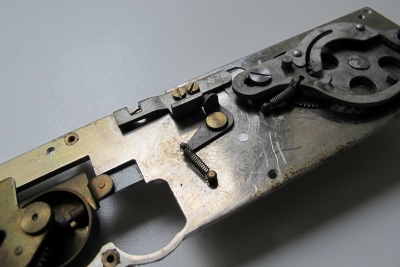

Next secret to be solved would be the shutter mechanism. The

Focal Plane shutter is expected to be the same as the Graflex shutter as it has

the same 4 slits which are visible from the outside when the ground glass back

has been removed. Winding the shutter is the same procedure as winding the

Graflex and the setting for front and rear shutter is also the same as Graflex.

The M.P.P shutter selector slide works exact the same as the Graflex but inside

you'll find different parts. The release mechanics are the same as the Graflex

parts, but they can't be interchanged due to minor differences. Finally the

wooden dark box. Almost every part seems to be interchangeable. I must admit I

didn't check that up till now.

Now we reach the elementary part of the rear shutter. The

focal plane shutter has two rollers. The one in the upper compartment has a

build in mechanic safety break to prevent winding the curtain further than its

length and thus the risk of tearing it off from the roller. The roller has a

square shaft end fitting into the bushing with a square hole. Inside the roller

there is a shaft with a thread and bolt. Winding the key the roller thread moves

the bolt to the end of a 2 inch long gap. Once the bolt reaches the end of the

gap, the curtain will be on the end of its travel along the film back. Hence the

winding can not be proceeded the fabric can not be torn off the roller. Great

invention!

The track and front standard look very much like the Graflex

Pacemaker Crown or Speed camera. Most of the M.P.P components are almost the same as used in the Speed

Graphic although not too many of them can be mutually exchanged. The lens

standard is almost 100 percent the same but has a different slider which is a bit thicker than

the one of the Graflex and thus wont fit on the track. Upper and lower roller

are different and not interchangeable. Track, back with ground glass, bed-brackets,

drop base board, housing including build in rangefinder. All

together it is easier to list the compatible parts such as the bellows, the build

in release knob and its build in mechanism, the release arm and lens board.

Tilt, slide and rising front nuts are exactly the same as the Graflex ones. The

camera back is equiped with a focusing panel which accepts film holders with the

raised lock rib trap. The springs are a bit different, but the working of the

back is exactly the same. The spring loaded focusing panel frame pulls back to

accept the Graphic type 5, Rightway, Lisco Regal II and other compatible 4x5

holders as well as the Graphic Grafmatic film holder. A closer inspection of the

camera shows the winding mechanism on the right side of the camera. The position

and the working of the winding key, the slide shutter selector, flash bi-post,

shutter speed control, the shutter speed window and lever at the bottom of the

plate cover are exactly like the Pacemaker Speed Graphic camera. However the

winding key itself is not interchangeable with the Graflex camera. Also the

mechanics inside have minor divergences and are not interchangeable.

Cleaning is essential for the good working.

Photos © Jo Lommen.

After a long period of time

and depending on bad storage conditions, the mechanic parts inside

should be cleaned thoroughly from dirt and old grease to prevent malfunction and slow shutter speeds.

Focusing bed, track, guides and yoke need some care after half a century, while

the curtain should be checked for light-leaks and rollers including the inside

springs should be cleaned to new

condition before renewing or replacing the curtain.

Without this maintenance the camera would be not reliable and thus worthless for photographing.

Also lens

and front shutter need attention and adjusting.

For more details about compatible and non compatible parts see:

Compatible and non

compatible Graflex parts

To find out all about the working read the:

M.P.P. Micropress Manual

Home

Jo Lommen Camera

Back

to European cameras