This is an old page. Here is more detailed info.

Spider silk is an extremely strong material and is on weight basis stronger than steel. It has been suggested that a pencil thick strand of silk could stop a Boeing 747 in flight.

The silk is used by the spider for a lot of different uses. Constructing their webs, the production of egg sacs, wrapping in their prey, as a life line when jumping, or dropping to escape, for transferring semen from the abdomen to the male palp, in drag lines marked with pheromones, as a shelter in which it can retreat.

Silk is for more than 50% a polymerized protein called fibroine with a molecular weight of 200.000 - 300.000. When looking at silk at a molecular scale one can see that the proteins strands are regularly orientated.

The silk is produced by the silk glands in the form of a liquid with a molecular weight of 30.000. As one would expect protein and other organic molecules distribution differs for the various types of silk the spider produces. Before the silk is released from the spinnerets it hardens (polymerizes). At least seven types of glands have been recognized. But there is no known family with all seven types.

There is a special gland (glandula aggregata) that produces the sticky material. The other six are:

gl. Ampulleceae major and minor for the production of the walking threads.

gl. Pyriformes for the attaching threads.

gl. Aciniformes produces silk for the encapsulation of the prey.

gl. Tubiliformes for the silk of the egg-sac.

gl. Coronatae threads for the axis of the sticking threads.

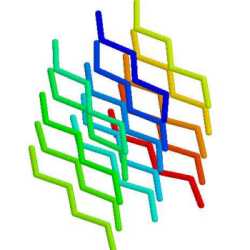

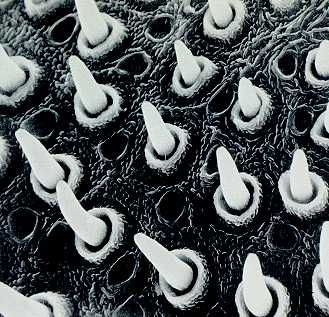

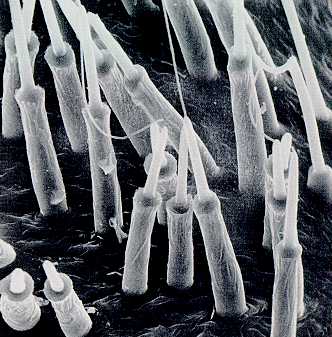

1 to 4 pairs of spinnerets release the silk. The cribellar glands are only found

in the cribellate spiders and this area contains small tubes ( 100 to even

50000) from which a strand is released with a smallest diameter of 0.00002 mm.

The scientific name of this region is: cribellum. Depending of the type

of silk that is to be made the spider mixes the fluid from the different glands

and regulates the speed and volume of release.

Two

types of silk releasing tubes. Picture from reference 7.

Two

types of silk releasing tubes. Picture from reference 7.

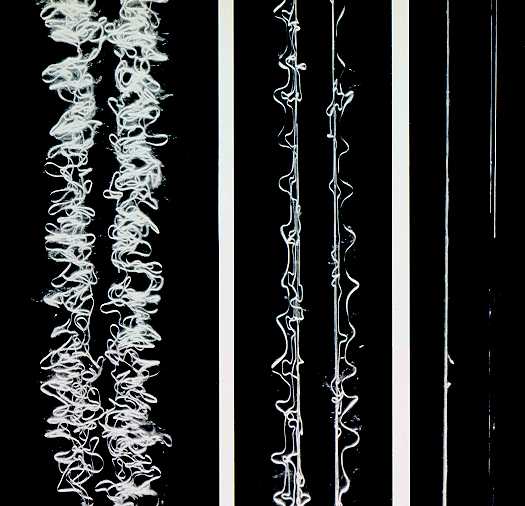

The material is elastic and only breaks at between 2 - 4 times its length. In the pictures a strand of a social spider, stegodyphus sarasinorum, is shown as normal size, stretched 5 times and 20 times its original length.

Picture

from reference 7.

Picture

from reference 7.

The spider can easily recycle the silk by eating it.

The web is easily destroyed by bad weather and by catching prey. After a day or

two the adhesive droplets of glue also lose their adhesiveness. The old web is

eaten and a new web is constructed again. The cutting and the digesting of the

web are done by special digestive juices that contain enzymes rather than by any

mechanical cutting. These juices are also used to connect the strands of silk

together.

DuPont's advertisement in the Scientific American of July 1996 tells us that they are studying these biopolymer structures of the spider webs. By using recombinant DNA technology they managed to produce analogs of silk in yeast and bacteria and are planning to use this synthesized material for all kind of construction purposes.

Ed Nieuwenhuys, 07 October, 1997